CIM - Flexible Manufacturing System

A Flexible Manufacturing System (FMS) is a configuration of computer-controlled, semiindependent workstations where materials are automatically handled and machine loaded. An FMS is a type of flexible automation system that builds on the programmable automation of NC and CNC machines. Programs and tooling setups can be changed with almost no loss of production time for moving from production of one product to the next. Such systems require a large initial investment but little direct labor to operate.

- Computer Integrated Manufacturing - CIM

Computer-integrated manufacturing (CIM) is an umbrella term for the total integration of product design and engineering, process planning, and manufacturing by means of complex computer systems.

Flexible Manufacturing System (FMS) is one of the tools used in Computer-Integrated Manufacturing or CIM.

Please click the link to read more about Computer-Integrated Manufacturing.

An FMS system has three key components:

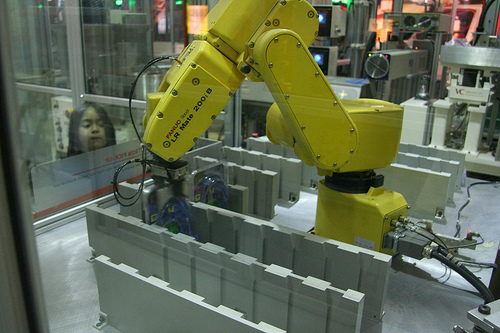

1. several computer-controlled workstations, such as CNC machines or robots, that perform a series of operations

2. a computer-controlled transport system for moving materials and parts from one machine to another and in and out of the system

3. loading and unloading stations

Workers bring raw materials for a part family to the loading points, where the FMS takes over. Computer-controlled transporters deliver the materials to various workstations where they pass through a specific sequence of operations unique to each part. The route is determined by the central computer. The goal of using FMS systems is to synchronize activities and maximize the system’s utilization. Because automation makes it possible to switch tools quickly, setup times for machines are short. This flexibility often allows one machine to perform an operation when another is down for maintenance and avoids bottlenecks by routing parts to another machine when one is busy.

Figure K.2 shows the layout of a typical FMS, which produces turning and machining centers.1 Specific characteristics of this FMS include the following:

❐ The computer control room (right) houses the main computer, which controls the transporter and sequence of operations.

❐ Three CNC machines, each with its own microprocessor, control the details of the machining process.

❐ Two AGVs, which travel around a 200-foot-long oval track, move materials on pallets to and from the CNCs. When the AGVs’ batteries run low, the central computer directs them to certain spots on the track for recharging.

❐ Indexing tables lie between each CNC and the track. Inbound pallets from an AGV are automatically transferred to the right side of the table, and out-bound pallets holding finished parts are transferred to the left side for pickup.

❐ A tool changer located behind each CNC loads and unloads tool magazines. Each magazine holds an assortment of tools. A machine automatically selects tools for the next specific operation. Changing from one tool to another takes only 2 minutes.

❐ Two load and unload stations are manually loaded by workers; loading takes 10 to 20 minutes.

❐ An automatic AS/RS (upper right) stores finished parts. The AGV transfers parts on its pallet to an indexing table, which then transfers them to the AS/RS. The process is reversed when parts are needed for assembly into finished products elsewhere in the plant.

This particular system fits processes involving medium-level variety (5 to 100 parts) and volume (annual production rates of 40 to 2,000 units per part). The system can simultaneously handle small batches of many products. In addition, an FMS can be used a second way: At any given time, an FMS can produce low-variety, high-volume products in much the same way that fixed manufacturing systems do. However, when these products reach the end of their life cycles, the FMS can be reprogrammed to accommodate a different product. This flexibility makes FMS very appealing, especially to operations where life cycles are short.

Since the first FMS was introduced in the mid-1960s, the number installed worldwide has grown to almost 500, with about half of them either in Japan or the United States and the other half in Europe. A much more popular version of flexible automation is the flexible manufacturing cell (FMC), which is a scaled-down version of FMS that consists of one or a very small group of NC machines that may or may not be linked to a materials handling mechanism. The FMC doesn’t have a materials handling system controlled by a computer, which moves parts to the appropriate machines, as does the more sophisticated FMS.

- CIM - Computer the Aided Design and Manufacturing

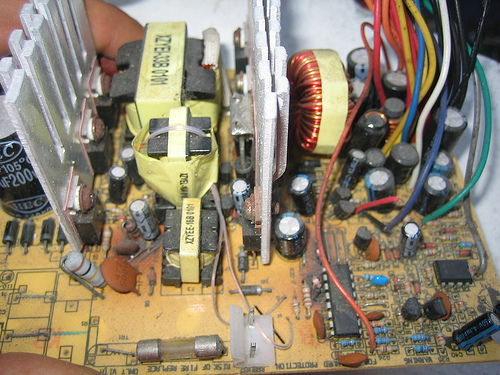

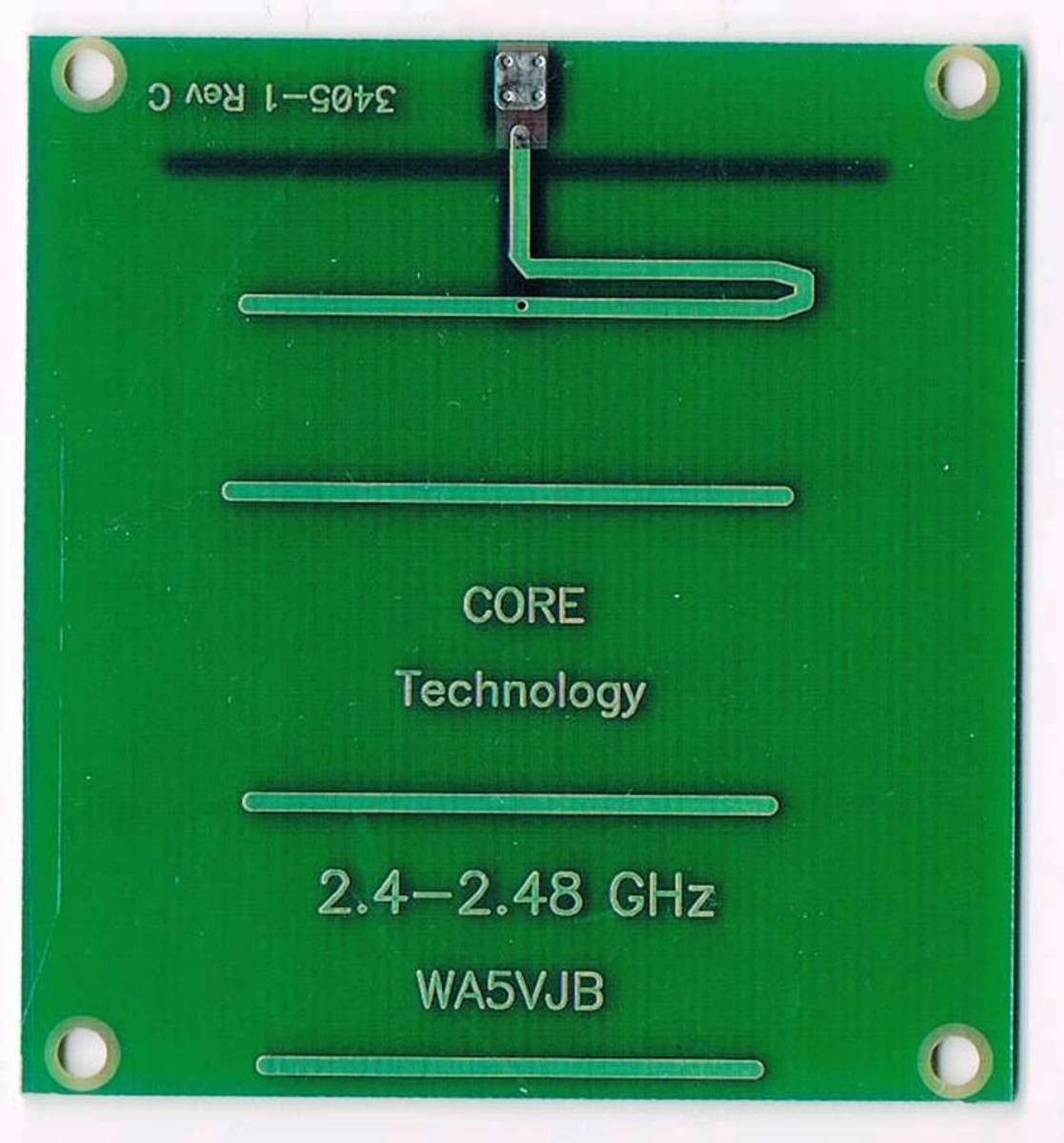

Computer-aided design (CAD) is an electronic system for designing new parts or products or altering existing ones, replacing drafting traditionally done by hand. The component of CIM that deals directly with manufacturing operations is called compute - CIM - Numerically controlled the machines & Industrial Robots

Numerically controlled (NC) machines are large machine tools programmed to produce small- to medium-sized batches of intricate parts. Industrial robots are versatile, computer-controlled machines programmed to perform various tasks. - CIM - Automated Materials the Handling

Materials handling covers the processes of moving, packaging, and storing a product. Moving, handling, and storing materials cost time and money but add no value to the product.